TEST PAGE Siemens

Ever tried to repair an old machine with new parts?

This was the global challenge faced by an industrial conglomerate in maintaining its customers' automation infrastructure. With machinery often dating back decades, different versions and upgrades of components, new item codes and changing suppliers had resulted in more than 500,000 products to be maintained in just one line-of-business.

Changing documentation and storage concepts for product data had intensified this needle in the haystack situation. Product management, key account managers and wholesalers faced difficulties in finding compatible components for maintenance and upgrade services. The existing product data management system of disparate relational files and applications had reach the end of the line.

- 98 % REDUCTIONOf Search Time

- 100 % SELF-SERVICEVia Web Interface

- 100 % SCALABLEFor Future Projects

INDUSTRY

Automation Technology & Electronics

Lorem ipsum dolor sit amet, consectetuer adipiscing elit. Aenean commodo ligula eget dolor. Aenean massa. Cum sociis natoque penatibus et magnis dis parturient montes, nascetur ridiculus mus.

PRODUCT USED

eccenca Corporate Memory

Our vision is a digital, agile supply chain that connects suppliers and customers through manufacturing by means of seamless data integration and e2e digitization of operations. With support of our semantic technology partner eccenca we gained an overarching understanding of our data enabling us to drive Industry 4.0 and Smart Supply Chain objectives effectively. To be frank, we never before had such a level of data transparency.

Karl Kirschenhofer

CEO

Challenge: Finding The Needle In The Haystack

Solution: Global Linking of 500,000+ Product Specs

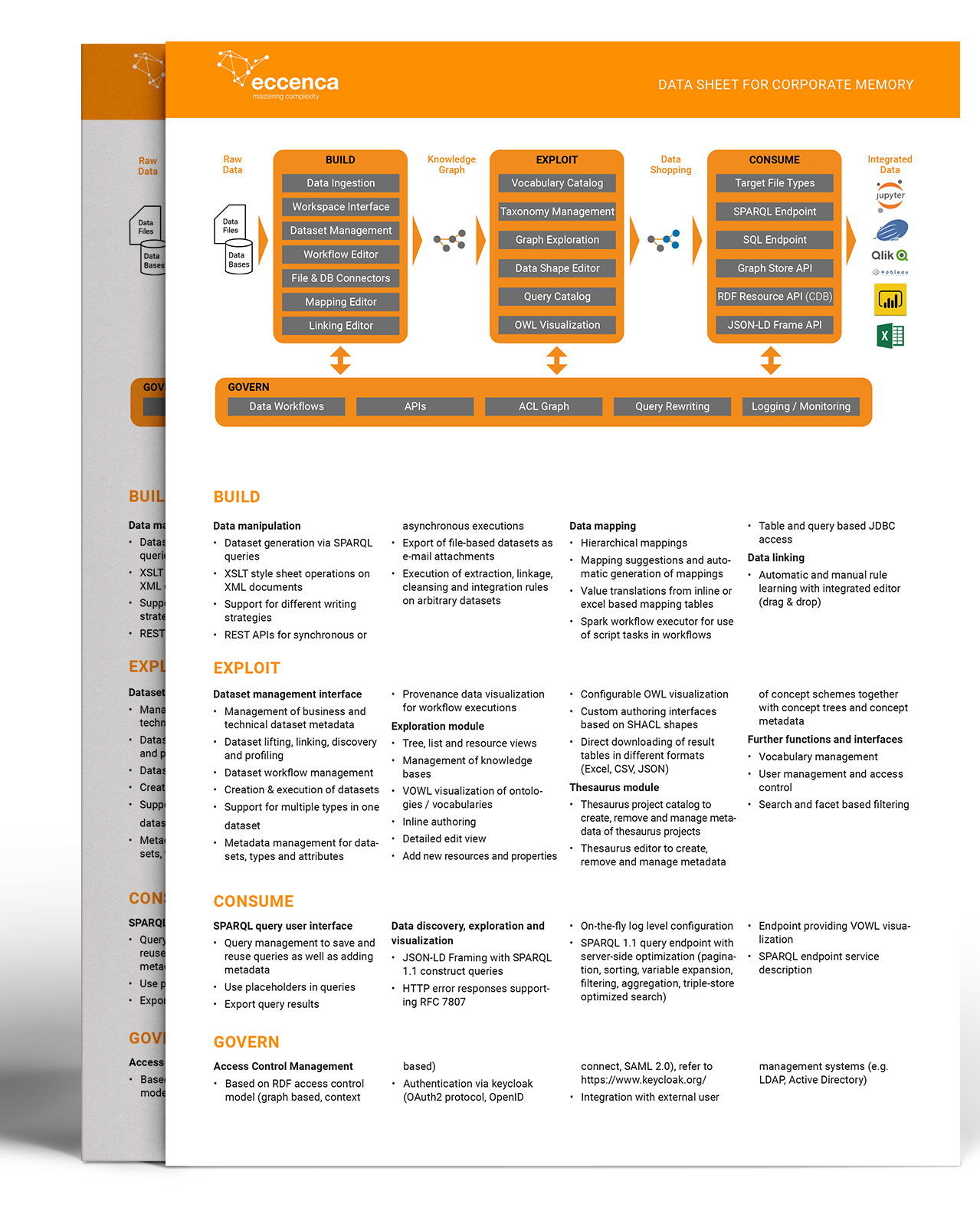

Using eccenca Corporate Memory the different data sources of more than 500,000 products and their descriptions were integrated in knowledge graphs. Each knowledge graph links data of a logical domain from different sources that can be automatically updated at defined intervals. Additionally, expert knowledge and metadata on machines and spare parts were added to profit from and share best practices. To browse the data landscape in its entirety the knowledge graphs can further be integrated into one overall „super graph“.

This intelligent update of the product data management system allows key account managers, wholesalers, installers and service technicians to compare all products on-the-fly via a simple web shop interfaces. Components can be searched by their specific attributes ensuring compatibility with older generations or outphased components. This reduces search time and increased findability by about 98 % leading to a significant minimization of downtimes in their own plants as well as client plants.